Where to be used / When to be applied?

Any firing Process where quality control is strictly required such as Fine Ceramics, Sanitary ware, Pottery, Porcelain and so on.

High temperature heat treatment process

Purposes and Applications

| Purposes | Applications |

| Process control & Optimization |

|

| Trouble shooting / Detecting Abnormality |

|

| Yield improvement |

|

| Improvement of product quality |

|

| Reduction of inspection time & costs |

|

| Quality Assurance |

|

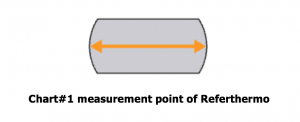

Fundamental principle of Referthermo

Referthermo is obtained by being pressed in the predetermined shape with ceramic powders such as alumina. As well as a common ceramics, when heat treatment is given, it is going to shrink and dense, and finally become dense ceramics. The dimension can be measured with a micrometer as shown below chart#1. ( * Please note that it should be measured after being left at room temperature more than a hour. ) Referthermo is a practical reference material in which raw material composition, particle distribution, molding density and so on are strictly controlled, and is a thermal history measurement senor utilizing a phenomenon of shrink and dense with good reproducibility according to firing conditions and thermal history.

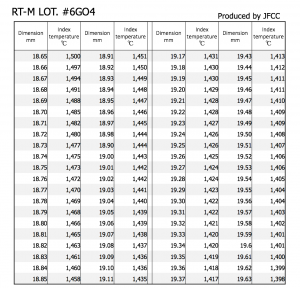

Effective use of the calculating table

The table sheet is made in use of temperature profile at 200Deg.C/hour rising, 2 hours retention and 300Deg.C/hour falling.

The index temperature is different from the actual temperature because of the different temperature profiles.

If you want to use the actual temperature as a index, you have to make your own table sheet by using your temperature profile so that you can make further accurate process control in your firing process.

Further, you can use the difference between actual temperature and index temperature as a corrective value of the temperature if you use it in narrow range.

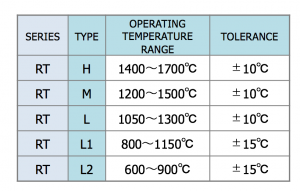

Operating Temperature Range by TYPE

How to select an appropriate TYPE

* The TYPE is sometimes failed to be selected at the operating temperature.

- You can easily select a TYPE in the guideline of the above table if retention time is 2 hours in air atmosphere. For examples, you can select M-TYPE at 1350Deg.C, L-TYPE at 1150Deg.C, and in case of 1250Deg.C, you can select an appropriate TYPE if you make sure which type is closer to the conversion chart in dimension by firing those two types together at your own firing conditions.

- Next, if which longer or shorter in retention time than 2 hours, longer retention time shifts a TYPE to high temperature type and shorter retention time shifts to low temperature type.

- Unless atmosphere is air, you have to ensure in advance testing at the conditions in consideration of the temperature and retention time.

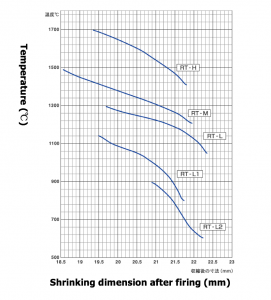

Correlation graph of shrinking dimension-temperature after firing